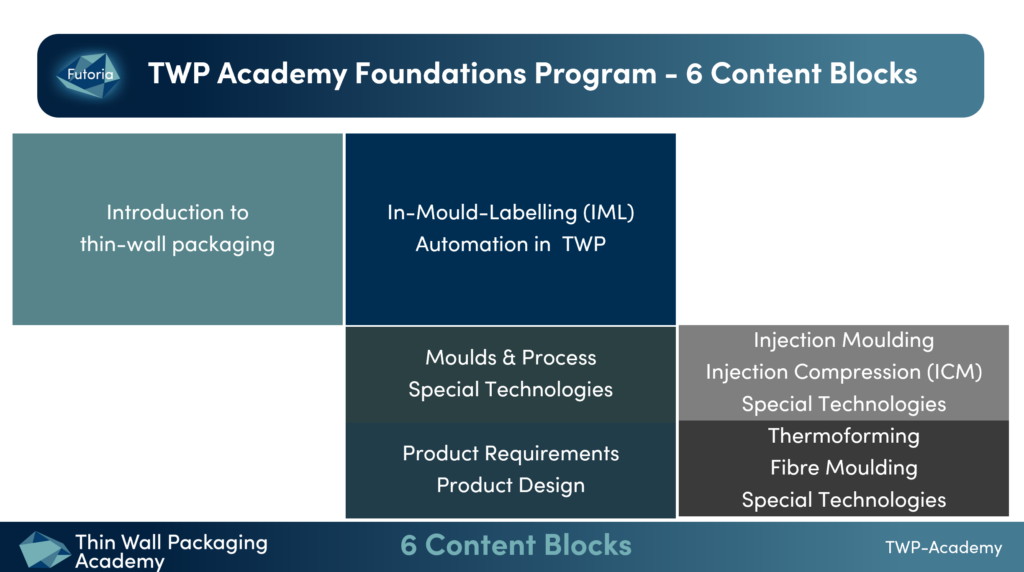

The Foundations Program 4 Course Modules

Let's start with a solid groundworkThe four modules form the foundation of the TWP Foundations Program, offering a structured and practice-oriented introduction to thin-wall packaging. Together, they build a solid technical and market understanding of key technologies, processes and applications, enabling participants to confidently navigate the world of thin-wall packaging and prepare for more advanced topics.

Module 1

Introduction to Thin-Wall Packaging

This module provides a structured introduction to Thin-Wall Packaging (TWP), covering key definitions, applications and market relevance. Participants gain a high-level understanding of Thermoforming, Injection Moulding and Injection Compression Moulding, including their basic differences. The module establishes a common technical and market foundation for all further TWP Academy modules.Find out more →

Module 2

Moulds, Process & Product Design in TWP

This module explains how mould design, process parameters and product requirements interact in thin-wall packaging. Participants gain insight into gating, flow behaviour, wall thickness, stacking and functional design features. Key quality drivers such as top load, dimensional stability and process robustness are addressed. The focus is on translating design decisions into stable, high-performance industrial production.Find out more →

Module 3

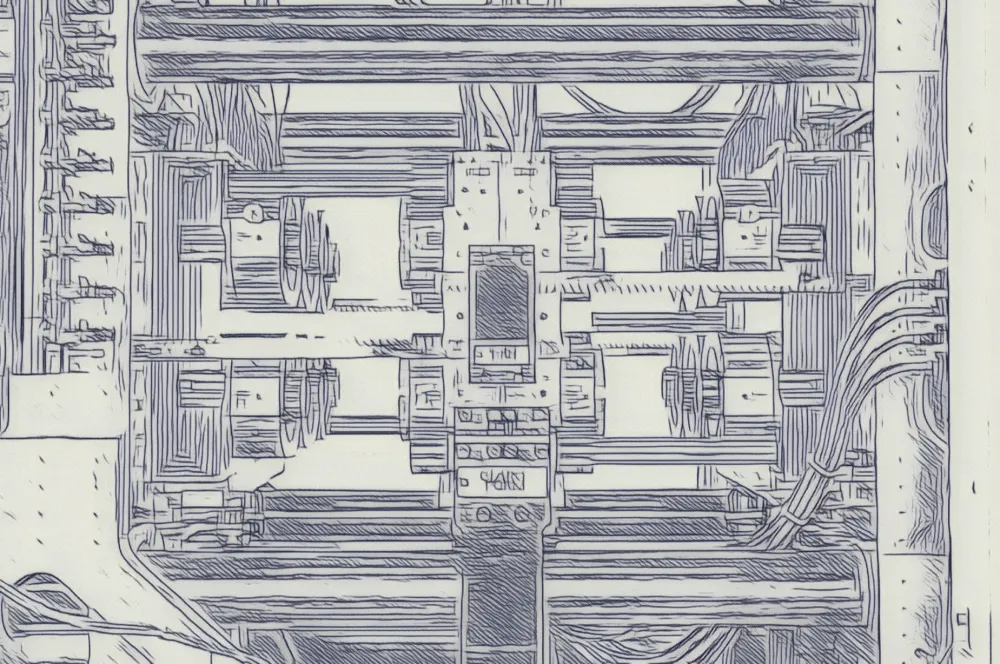

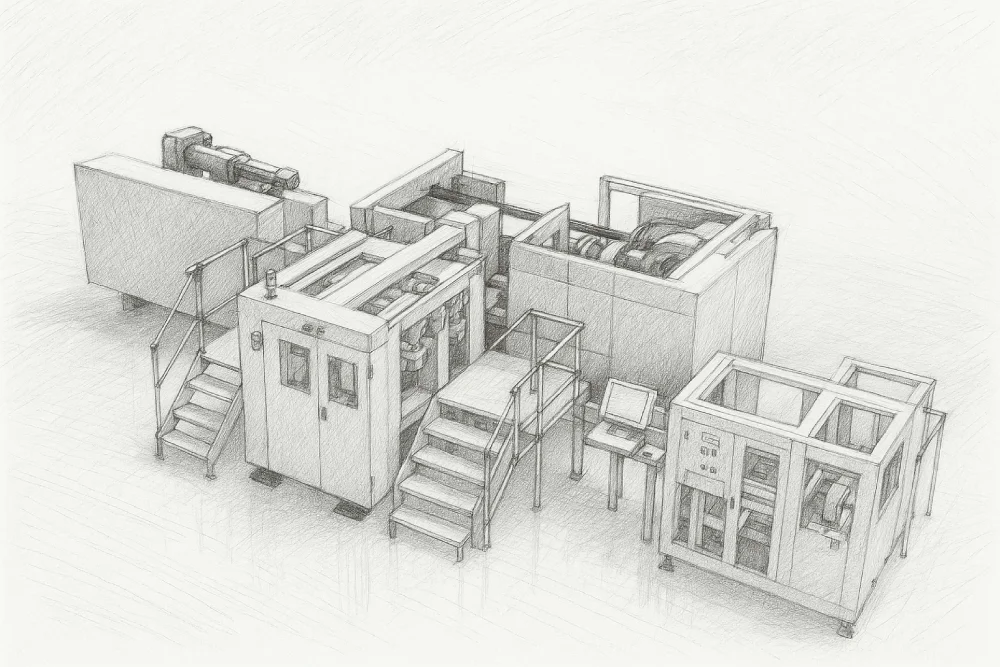

Automation & IML in TWP

This module takes you inside the world of automation and in-mould labelling (IML). Learn how IML works, what makes it unique compared to other decoration methods and why it’s a growing choice in packaging. Explore label types and functions, automation and vision systems, as well as stacking solutions. Explore diferent perspectives by comparing the views of brand owners, manufacturers, retailers and consumers.Find out more →

Module 4

Packaging Technologies & Processes

Dive into core TWP manufacturing methods: Injection Moulding (IM), Injection Compression Moulding (ICM), Thermoforming, Barrier & Co-injection Technology, 2-Component/Colour applications, Pulp Injection (Fibre Moulding), PET in thin-wall applications and others. Analyse production performance and estimate key process data. Develop confi dence in cross-functional packaging discussions and technical evaluationsFind out more →